Coordinator: Prof. Dr. André Luis Jesus Pereira

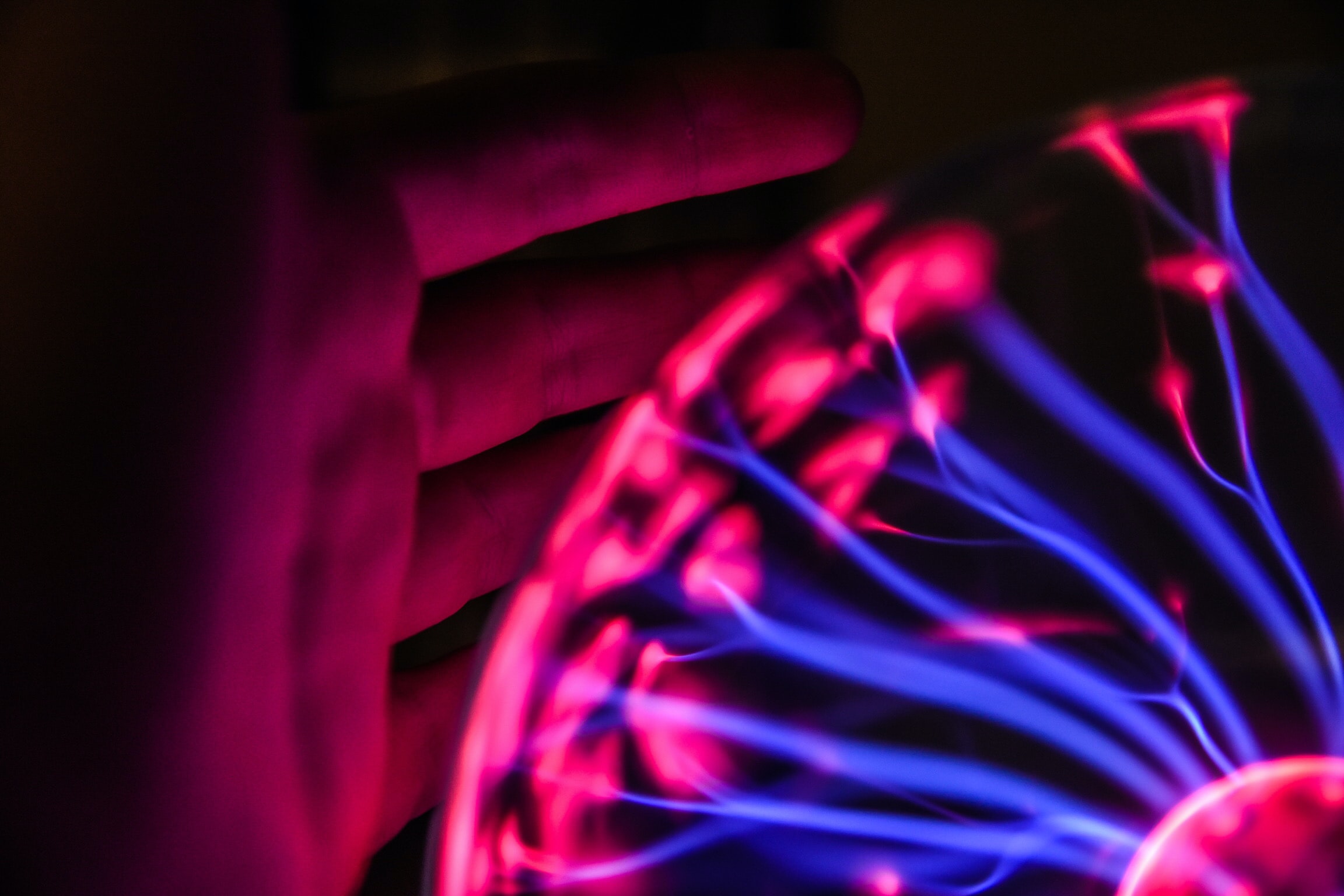

Studies are carried out on hot and cold plasmas applied to controlled thermonuclear fusion and plasma technologies aimed at the development of devices for material treatment and thin film deposition. Applications include nanotechnology, material treatment (microelectronics, mechanics, aerospace, energy, dentistry and medicine), sensors based on thin films, ozone generators (medicine and environment) and plasma assisted combustion.

Research topics:

- Superficial alteration of polymers by means of plasmas

- Use of various types of electrical discharges (radio frequency, microwave and dielectric barrier) and post-discharges to change the adhesion properties of aerospace rubbers

- Characterization of carbon-based nanostructured films

- Study morphology, lubricity, adhesion and hardness, as well as characterization of the chemical structure, surface energy and chemical inertia of nanostructured thin films based on carbon with and without incorporation of metallic, semi-metallic nanoparticles and carbon nanotubes, grown on substrates low carbon steel, stainless steel, titanium alloy, iconel, silicon and oxides. Common substrates in the aerospace and microelectronics industry in general.

- Characterization of materials obtained by plasma technology

- Study of electrical, mechanical, surface, optical and thermal characteristics of materials of interest obtained or modified by plasma assisted techniques

- The materials under study are of interest to various industrial sectors, such as aeronautics, space, mechanics, micro and nanoelectronics

- Development of sensors based on thin films

- Develop methodologies for obtaining thin films with adequate characteristics for making pressure sensors, accelerometers and Stockky diodes

- Development and study of vacuum reactors for cold plasma production

- Develop and characterize plasma reactors for application in material processing

- Work with reactors that operate with different types of voltage sources, highlighting: CC, RF and microwave

- Develop plasma sources for generating jets, in the form of a plasma beam or a beam of charged particles extracted from plasmas

- Development and study of reactors for plasma production at sub-atmospheric pressures

- Develop reactors obtained by micro discharges

- Develop dielectric barrier reactors for ozone production

- Develop materials surface treatment processes

- Develop thermally stabilized synthetic fiber treatment processes

- Develop reactors for ozone production for application in washing hospital clothes

- Develop reactors for the production of ozone for application in the treatment of drinking water and sewage

- Study of plasma assisted combustion

- Reduce NOx production in the combustion process

- Improve combustion stability

- Study and applications of thermal plasmas

- Develop thermal plasma processes to treat solid residues and petroleum residues with electricity generation

- Ablation of thermo-structural materials used as a thermal protection shield

- Develop and characterize plasma jets for simulating the atmospheric reentry environment for aerospace application

- Plasma-assisted gasification

- Develop alternative technology to the existing gasification of biomass, coal and organic waste for the production of synthesis gas

- Instrumentation and control of vacuum chambers and plasma reactors

- Develop the necessary instrumentation to automate processes using plasma-assisted techniques

- Modeling and numerical simulation in cold plasmas

- Simulation of electrical discharges for application in plasma material processing

- Synthesis and modification of materials by means of cold plasmas

- Develop plasma processes that make it possible to obtain:

- Dielectric materials for application in micro and nanotechnology, such as SiC, AlN, DLC and TiO2

- Semiconductor materials for application in micro and nano technology, such as nitrogenous and fluorinated DLC films

- Biomaterials based on coating with DLC films

- Develop processes for incorporating silver nanoparticles in diamond-type carbon films for aerospace application

- Develop plasma processes that make it possible to obtain:

- Water treatment by ozone technology

- Micro and nanoscale tribology

- To study lubrication and wear problems of carbon-based film coatings, deposited via plasma on, stainless steel, low carbon steel and silicon in an ambient atmosphere, in a vacuum, in brackish water and in distilled water. Study hybrid lubrication involving coatings based on nanostructured carbon in brackish water, in biofuels and evaluate the losses due to friction and wear in pairs with and without coatings between the pairs in contact

- Use of cold and thermal plasmas in nanotechnology

- Production of carbon nanotubes by plasma assisted techniques

- Produce nanoparticles by plasma assisted techniques

Permanent Professors:

- Prof. Dr. Argemiro Soares da Silva Sobrinho: Plasma Materials Processing.

- Prof. Dr. André Luis de Jesus Pereira: Semiconductor oxides

- Prof. Dr. Homero Santiago Maciel: Electric Discharges. Technological Applications of Cold Plasmas.

- Prof. Dr. Rodrigo Sávio Pessoa: Condensed Matter Physics and Plasma Physics.